Boardrooms, we have a problem. And it’s an urgent one. We must remake our entire industrial system—the intricate and finely tuned set of networks that feed us, move us around, and build, make, and power the things we use every day. Today’s industrial system developed over several decades—and, in some instances, even centuries. But we have only ten to 15 years to completely reconfigure it. Unless we do, the greenhouse gases that our 19th- and 20th-century system emits are going to create irreversible damage to societies and our planet before the middle of the 21st century.

The responses from executives to this admittedly alarmist challenge tend to align along two poles. On one side are the ultrapractical incrementalists: “We need to be realistic. There’s no way we will wean ourselves off hydrocarbons over the next decade or two.” And indeed, we’re a long way from generating enough renewable power, having sufficient transmission and storage capacity, electrifying all our industrial processes, having a fully electric fleet of vehicles with the required charging infrastructure, or using low–carbon-emitting agricultural practices at a scale where they can feed the world. There are many vast critical gaps that need to be bridged.

On the other side stand the audacious revolutionaries. “We don’t have a choice. Just do it. Now.” They, too, are right. If we miss net-zero targets by too much, crops will fail, oceans will rise, and wet-bulb temperatures will increase to a point where humans will overheat because their sweat can’t evaporate. This will unleash unimaginable suffering on societies. And it will also harm economies and wreak massive havoc on balance sheets.

These responses are both right in some ways but wrong in others. Stop using hydrocarbons before climate-friendly alternatives are ready to take over, and we would be left without the fertilizers that farmers need to produce our food; without the energy to heat and light our houses, schools, hospitals, and offices; without the cement, steel, aluminum, and glass to build houses, roads, cars, trains, solar panels, and wind turbines. But we also can’t rely solely on incremental no-regret steps, continuous improvement, and companies seeking opportunities to cut greenhouse gas emissions and selecting their suppliers according to sustainability criteria. These are necessary but not sufficient. Change trickling through the system in this way would take much more time than we have left.

To solve this problem of a lifetime, we must chart a path between these two poles. We need to be both radically audacious and incredibly practical: radically audacious in questioning all our previous assumptions and in scaling solutions massively and fast, and incredibly practical in developing realistic plans and overcoming the powerful forces of inertia so we can accelerate progress. We have to articulate a vision of what the future state looks like and embark upon the concerted and parallel efforts to reconfigure the ecosystems in which we work and transform our own organizations.

value in motion video thumb

Confronting the forces of inertia

There are many reasons to be optimistic. Most of the components needed to transition to a carbon-neutral industrial system exist. These include:

- adaptive multi-paddock grazing that allows for carbon-negative cattle raising

- drought-resistant crops that produce higher yields under adverse climatic conditions

- cement plants that add captured CO2 to fortify the end product and therefore act as a carbon sink

- electric vehicles whose range and price are increasingly competitive with vehicles that have internal combustion engines

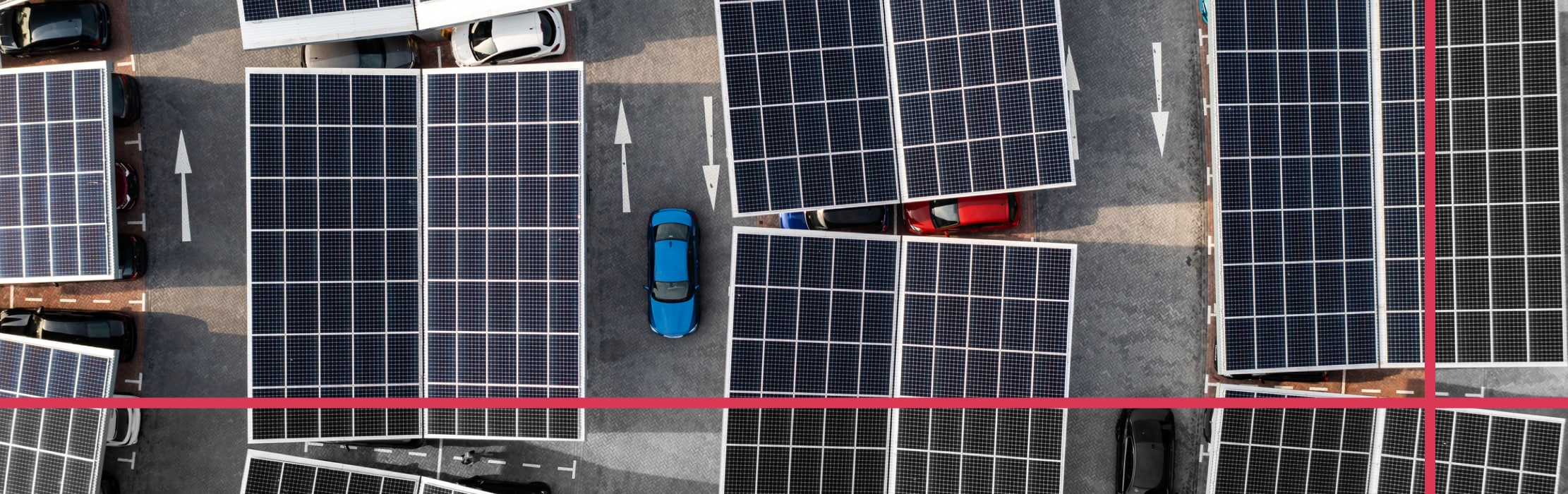

- highly effective solar panels and wind turbines that provide us with the cleanest energy at the lowest cost.

In those areas where commercial solutions don’t yet exist, innovation—such as cost-effective, multiday energy storage systems that help balance the variability in renewable electricity generation—seems to be just around the corner.

So with all these solutions available, why does transitioning to a sustainable world seem to be an insurmountable task? Well, there’s a lot of inertia built into our systems. The massive systemic change that’s required is slowed by a number of factors.

Interdependencies:

Reconfiguring the industrial system requires the transformation of thousands of players that are highly interdependent. Even one player falling behind or failing to develop sufficient capacity can slow down the entire reconfiguration. We’ve already seen how a shortage of semiconductors can bring auto production to a halt. Just so, many key industrial processes can’t be decarbonized without green hydrogen being available in sufficient quantities and at competitive prices, powered by renewables that don’t yet exist, and delivered through pipelines that have yet to be built. Any of those instrumental factors failing to come through in time will delay the decarbonization of those critical processes.

Massive investment needs:

The reconfiguration necessitates massive capital investments that aren’t happening organically, especially now that we’ve entered an era in which money and capital are likely to be more expensive for an extended period of time. The market doesn’t magically direct the flow of capital to the areas where it’s most needed. (The US, with its healthy venture capital and private equity markets, is better off than many other regions.) PwC’s recently released State of Climate Tech 2023 report found, for example, that the largest share of climate tech investments currently flows into mobility and transport but that sectors such as construction, buildings, and agriculture, which also account for large amounts of emissions, are substantially underfunded.

Stranded assets:

Although there will be huge winners in the reconfiguration of the world’s industrial system and massive growth in certain sectors, there will surely be losers and declines in well-established industries and businesses. Incumbents have resisted technological paradigm shifts, sometimes fiercely, since the advent of the Industrial Revolution. So it’s not surprising that organizations and people fearful of a loss of value—owners of oil and coal fields who will find the value of their reserves dwindling, or gas stations and oil-change shops that will be affected by the transition to electric vehicles—may drag their feet, erect barriers, and focus on preserving what they have.

Slow technology adoption:

Although many of the key technologies that are required for the reconfiguration of the industrial system are either on the market or imminently available, adoption is often slow because of high investment needs and the reliance on existing products and services, the existence of long-term contracts, and the human tendency to wait for something even better and cheaper. Cost-effective energy storage, for example, is needed to bridge gaps between variable generation of and demand for renewable power. But because prices for batteries are comparatively high and cost curves are projected to bend rapidly, it may often make sense to wait a few years to make investments. A deal struck for battery storage in 2025 is likely to offer an entirely different payback schedule than one struck in 2023.

Missing critical regulations:

Reconfiguring the industrial system, which itself has been shaped by decades of regulatory policy, requires a new set of regulations. But in an increasingly complex and polarized world, governments often struggle to pass and enforce far-reaching regulations. Carbon exchanges and carbon certificates are topics of massive political debate, and even regulations that are generally considered as unavoidable, such as those aimed at speeding up the construction of critical infrastructure, aren’t passed as quickly as they need to be.

To overcome the significant forces of inertia and resistance, organizations will have to marshal all their forces effectively and efficiently. We won’t be able to accelerate our progress without addressing all of these factors. It’s therefore easy to see why companies’ traditional approach of managing change solely by focusing on their organizations, teams, and individuals needs to change as well.

Audaciously practical ecosystem management

Given the urgency to transition to a sustainable world, entire ecosystems must shift rapidly as they adapt to the new commercial realities being created in front of our eyes. In the past, an innovator might introduce a new technology or a new way of doing things, and it would cascade through its ecosystem—and help form a new one—over the course of several decades. The advent of the personal computer stands as one such example. But today, change has to happen more quickly. What is therefore needed is a clear and far-reaching view of what the major ecosystems should look like in the future, a view of where companies see their place in them, and a practical approach to help encourage the ecosystems’ development.

To take one example, the future smart mobility ecosystem looks very different from the personal mobility by road ecosystem of 2013, or even 2020. It includes electricity generators and transmitters, mining companies, battery producers and recyclers, charging station builders and owners, automotive companies (components and assemblers), car dealers and vehicle repair shops, fleet operators and car-sharing companies, insurance companies, software companies that enable autonomous driving, and many more. The many interdependencies among them are both obvious and highly complex. And these developments are putting immense amounts of value into motion. For the transition to a sustainable world to happen, all of these players must do new things in new ways.

If you’re running an organization or supervising its management, the task at hand is to envision the future ecosystem in which you intend to operate. Beyond understanding what types of companies will perform what roles, you have to develop a clear view on how value pools are going to shift. What highly profitable activities will dwindle or disappear? And which small puddles of profits will develop into deep pools that your organization can tap? What parts of the value ecosystem are you going to focus on? How will you create value in the future? Whom will you depend on to do so? What is likely to slow you down, and what could help you accelerate progress?

Once this positioning is determined, you can then become practical in aligning the ecosystem and shaping it. This may mean leaning in to one of several levers, including the following:

Striking partnerships or joint ventures

to formally align actions with players you depend on. Consider the RWE-BASF Offshore-to-X project. Led by the chemicals giant BASF and RWE, a large utility headquartered in Germany that focuses on renewables, this partnership will enable BASF to replace CO2 -intensive processes for basic chemical production at its Ludwigshafen site with innovative CO2 -free technologies. RWE and BASF will produce the required green electricity in a 2-gigawatt (GW) offshore wind park, to be built in the German North Sea. RWE will deploy the electricity not used by BASF’s site to produce green hydrogen.

Vertically integrating

to reduce the number of external dependencies. Reliance Industries, a multinational conglomerate headquartered in India, is investing more than US$10 billion in building a comprehensive ecosystem for new energy and new materials in India. It will include everything from transforming sand into solar photovoltaic modules, from producing carbon fiber to manufacturing wind turbines, from producing battery chemicals to manufacturing cells, packs and containerized energy-storage solutions. The goal is to install 100 GW of renewable energy capacity by 2030.

Developing local solutions

that allow you to bring everyone you need together to plan and advance solutions. Babcock Ranch, a development in Florida roughly the size of Manhattan, was built to be climate resilient. It includes lakes that serve as retaining ponds to protect houses from floods, streets that are designed to absorb excess rainfall, and a community hall that is reinforced as a storm shelter. The entire development as well as surrounding communities is powered by an 870-acre solar panel farm. Hurricane Ian in 2022 was the development’s first test—and the city did better than expected. Not a single house lost power, internet, or access to clean water. A few upturned palm trees and street signs were about all the damage suffered.

Working with aggregators or agencies

that have the power to move entire ecosystems. The Ontario Vehicle Innovation Network (OVIN) has been put in place by the province’s government to drive innovation and investment across Ontario’s electric, connected, and autonomous vehicle sector. Acting as a hub for the province-wide coordination of activities and resources, OVIN aims to put Ontario at the forefront of global demand for cleaner, safer, more sustainable transportation solutions by facilitating the development of the complex mobility ecosystem.

All these levers, and other practical interventions, have the power to mitigate some of the factors that would otherwise slow you down and to move the ecosystem in the direction you need it to go.

Audaciously practical internal reinvention

Although driving change at the ecosystem level is more important than ever, you also must get your own house in order. Be ambitious when staking out your future position. What is it that stakeholders really want and need—not just customers, but also end consumers, society at large, suppliers, business partners, investors, regulators, etc.? How can you create value in fundamentally new ways? Answering these questions will probably lead to the realization that you have a lot of work to do at the organizational, team, and individual level.

At the organizational level, you’ll need to get investors on board by engaging them around your view of the future and helping them understand your target positioning, why it’s the right one for you, how you’re going to get there, what the risks in transforming (and not transforming) are, and the expected impact on your company’s performance. This is necessary especially in case there are trade-offs such as short-term pain for longer-term gain. For example, a ten-year project to decarbonize steel production might require a significant capital expenditure but has the potential to yield a series of business advantages that may materialize only in a future ecosystem: premium pricing, security from carbon taxes, and the ability to compete for carbon-free government contracts. Doing this requires you to define new measures of valuation that recognize that the net present value of not transforming is very negative due to the accelerating impact of balance sheets.

Make sure that people recognize how big and urgent the issue is, while feeling a sense of agency. What can individuals do to advance the company and thereby the reconfiguration of the entire ecosystem?

More than ever, you’ll also have to become fit for growth—cut bad costs, invest in good costs, and develop differentiated capabilities. In a nutshell, it means being highly efficient at what you’re doing today to free up the investment bandwidth required to build the capabilities you’ll need to thrive in the future. That doesn’t mean, however, that you’re not investing in your current business anymore; you must keep it running and adapting to the changing world until the new system is ready to take over.

When it comes to leadership, you may have to expand your current executive team to include experts in specific areas that are critical for your company’s future success, such as AI or green tech. In a world as complex and interdependent as ours, you will also need to have the entire executive team own the change, rather than putting one or two functional leaders in charge.

What’s more, you need new mechanisms that account for the fact that answers to many questions don’t yet exist and might have to be developed as you make progress. This will require new formats for solving problems together rather than presenting solutions and seeking approval, as well as new ways of tracking progress and rewarding people.

At the personal level, you’ll need to make sure that individuals recognize how big and urgent the issue is, while feeling a sense of agency. Having a view of how the entire ecosystem must evolve and what role your organization plays in that is a key component, but it has to be further broken down to what it means for individuals inside the organization—what they can do to advance the company and thereby the reconfiguration of the entire ecosystem.

You’ll also have to deal with the fact that people who are proficient at their current job might resist change because they’re concerned they may not be good at what they’ll be required to do in the future. Acknowledge the concern, reassure them you’re in it together, ask them to be curious and be open to learn, have managers work with everyone on what it takes to be successful in the future world, and invest heavily in upskilling programs.

Reconfiguring the industrial system is the problem of a lifetime. But if we combine radical audacity with incredible practicality, we have the opportunity to solve the climate crisis and build a future that is brighter, more just, and more resilient.

Ryan Hawk is PwC’s global industrial manufacturing and automotive leader. Based in Chicago, he is a principal with PwC US.

Nadia Kubis is a member of the global strategy and leadership team at PwC. Based in Cologne, she is a senior manager with PwC Germany.

Blair Sheppard is PwC's global leader, strategy and leadership. He leads a team that is responsible for articulating PwC’s global strategy across 151 countries and the development of current and next-generation PwC leaders. He is professor emeritus and dean emeritus of Duke University’s Fuqua School of Business and is based in Durham, N.C.

Contact us